Engineering Apprenticeship

Learn Practical Engineering Skills

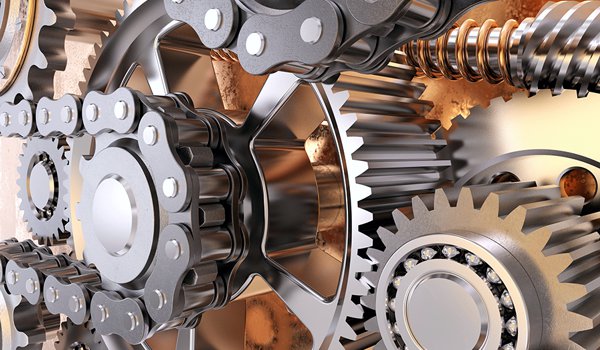

In addition to their academic sessions, apprentices develop practical skills in line with the core business of Hydram, which leads towards an NVQ level 3.

Apprentices gain not only the technical knowledge which is delivered onsite by members of Hydram’s training team, but also the necessary practical skills on the latest production machinery: