Starting on dayshift for day 1 induction, then moving straight onto a 2 shift rotation, this person should be capable of carrying out high-quality spot and projection welding on a variety of sheet metal components.

They should have good attention to detail, be able to follow standard operating procedures, and feel confident working with jigs, fixtures, and basic measuring tools.

Experience within a sheet metal or manufacturing environment is desirable, and this person should be comfortable reading and understanding engineering drawings.

They will be expected to work independently, manage their workload effectively, and ensure all parts meet the required quality standards.

You can submit your CV by following this link >

Hydram Sheet Metalwork is a leading supplier of sheet metal and tubular components, assemblies and light fabrications to customers throughout the UK employing over 200 people.

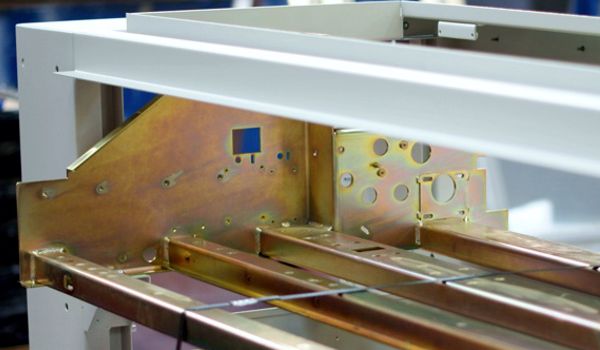

The precision fabrication company provides the full range of subcontract engineering services, including tube and sheet laser cutting, tube and sheet bending, fabrication, powder coating and assembly from its 135,000 sq ft factory in County Durham.

Hydram supplies components and sheet metal fabrications to market-leading companies in industries such as transportation, electrical cabinets, earth-moving machinery and white goods.

Hydram – your complete manufacturing partner.