As your custom fabrications manufacturing partner, Hydram Sheet Metalwork manages customer projects professionally and thoroughly from design to manufacture, paying the utmost attention to quality, cost control and delivery performance.

With dedicated account managers, experienced engineering and quality teams all working together, Hydram is one of the top UK precision custom fabrication companies.

As a leading sheet metal fabricator, Hydram has a long history of developing successful long-term partnerships with customers, working closely to provide outstanding manufacturing services in the custom precision sheet metal fabrication market.

A team of dedicated account managers are the customer’s primary contact throughout their dealings with Hydram, from initial enquiry through to daily administration of deliveries and are the customer’s representative within the business.

The account managers are backed up by a team of Project Engineers and Design Engineers who are keen to offer customers the benefit of Hydram’s 40 years of manufacturing know-how and experience in manufacturing custom precision sheet metal fabrications, to provide cost effective, high quality solutions.

The engineering team make extensive use of industry-leading computer aided design and 3D modelling packages, together with CADCAM systems to provide product simulations.

The team is equally happy working to concepts or detail designs. They often suggest small changes to design detail that make big improvements to efficiency, streamlining manufacturing processes to make them leaner, with the aim being to reduce costs, without compromising quality or the design intent of your custom fabrications.

Hydram Sheet Metalwork develops long-term partnerships with market leading companies in industries such as railway, public transport, lighting, furniture, earth-moving machinery/off-road vehicles and white goods.

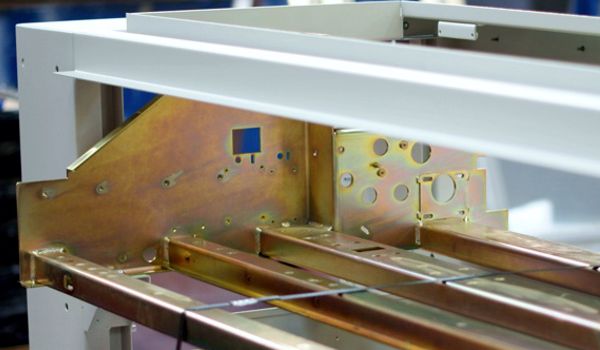

Hydram supplies fabrications and metal parts made from mild steel, stainless steel and aluminium, often including CNC machined metal parts, as well as using sheet metal fabrication processes.

The ISO 9001 certified sheet metal custom fabrications company is committed to providing outstanding manufacturing services within the precision metal fabrication sector.

Hydram – Your Complete Manufacturing Partner.

Hydram owns three Bystronic laser cutting machines and two Trumpf punching machines all of them complete with tower storage and full automation. The plant list also includes a total of fourteen multi-axis pressbrakes, three robotic welding cells, four powder coating lines, CNC machining and much more. With over 40 years experience, extensive capacity and thorough ISO approvals, Hydram is positioned as one of the leading precision fabrication companies within the UK subcontract metalwork market.

As one of the UK’s best custom fabrication companies, Hydram is a professional and thorough supply chain partner, with the management of quality, competitiveness, and delivery schedule adherence its top priorities.

Based in the North East of England, Hydram boasts a 135,000 square foot facility at its site in Chilton, where it has been manufacturing precision sheet metal fabrications since 1977, and offering impressive metalwork production capacity for sheet metal fabrications.

With a long history of developing successful long-term business relationships with customers in a broad range of industry sectors, Hydram has an experienced team of sales engineers, account managers and quality engineers, working to ensure the highest level of customer service.

Hydram is proud to be considered as one of the UK’s top custom sheet metal fabrication companies in the UK. Contact our team to discuss how we can help with your custom fabrications project.

Hydram Machinery List

Sheet Metalworking Insights

Quality, sheet metal fabrications

Find out more

Custom fabrication quality certification

Choosing custom fabrication companies

Company History Since 1977

Safety, Health and Environment