Precision Metalwork Companies

Hydram works closely with associate sheet metal companies within the Dynamic Metals Group accessing knowledge and expertise across a wide range of industrial sectors. Dynamic is a privately-owned business with its main headquarters in Michigan USA, comprising of a group of companies based in the US mid-west and the UK, having an established reputation specialising in supplying precision metal components for the aerospace, defence, automotive and rail sectors.

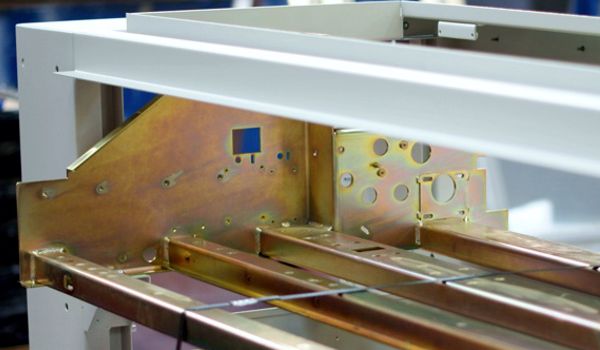

From very small stamped precision spherical washers for high-pressure hydraulic applications to very large transition duct components to support power generation, the variety of products produced by the group is impressive.

Dynamic group companies manufacture metal products such as mechanical components for all types of specialty transportation equipment including heavy-duty structural fabrications for large earth-moving equipment, steel products for agricultural equipment, off-road equipment, and other heavy duty applications, through to interior trim fabrications finished to the highest standard.